Customer-oriented project planning

- Flexible - constructions according to requirements

- Robust - easy to maintain

- Upstream and downstream conveyor technology

Safe filling and emptying of all BIG-BAG sizes with or without inliner, for free-flowing or heavy-flowing, dusty or aggressive products. HUMBERT & POL develops the tailor-made solution with you. HUMBERT & POL filling and discharge stations are optimally adapted to future operating conditions by our engineers and can be extended by a wide range of components.

Big bag handling

Simple handling

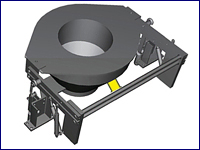

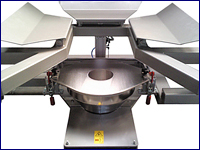

Adapted to the installation site and filling product, the HUMBERT & POL BIG BAG filling and emptying stations enable dust-free operation when emptying and filling almost all powdered and granular bulk materials from or into BIG BAGs in standard commercial sizes.

Adapted to the installation site and filling product, the HUMBERT & POL BIG BAG filling and emptying stations enable dust-free operation when emptying and filling almost all powdered and granular bulk materials from or into BIG BAGs in standard commercial sizes.

The individual design, optionally in mild or stainless steel, and the space-saving, robust construction ensure easy handling as well as efficient and therefore economical production processes. The innovative modular design allows existing stations to be expanded at any time. Integration into upstream and/or downstream conveyor systems is possible without any problems and makes the HUMBERT & POL BIG-BAG station an important link in the production chain.

The individual design, optionally in mild or stainless steel, and the space-saving, robust construction ensure easy handling as well as efficient and therefore economical production processes. The innovative modular design allows existing stations to be expanded at any time. Integration into upstream and/or downstream conveyor systems is possible without any problems and makes the HUMBERT & POL BIG-BAG station an important link in the production chain.Big bag handling

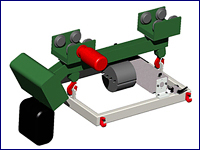

Special applications & options

The HUMBERT & POL BIG-BAG filling and discharge stations can basically be integrated into an upstream or downstream conveyor system. In addition to special equipment such as dust-free docking with a double pipe or, in the case of non-dusting products, discharge into a receiving hopper, the stations can be designed with many additional options:

- Gantry construction with chain hoist

- Traversing device for chain hoist

- Residual emptying by automatic retensioning device

- Pneumatic winding device for inliner pullout

- Pneumatic discharge aid

Further extras are available:

- Weighing

- Extension with a manual feeding station for bags, cartons, etc.

- Filling stations with vibrating plate for optimal filling

- Loading harnesses for stationary loading with forklift truck

- Design according to directive 2014/34/EU (ATEX)